The IoT is regarded as the third wave of the information industry after the computer and the Internet. In the process of its realization, it needs the cooperation of many high and new technologies. RFID, as one of the top ten important technologies in the 21 century, is an important cornerstone of the IoT. Combined with the Internet, communication, and other technologies, RFID can achieve global tracking and information sharing. RFID tags are the most critical and well-known part, which has gone deep into our daily life.

Nowadays, RFID tags appear in our vision in various forms, making our life more convenient and intelligent. RFID chips can be attached to almost anywhere: clothes, shoes, vehicles, containers, and even plants, animals, and humans (as implants). Microchips are even attached to insects. Today, let’s take a closer look at the RFID tag and unveil it.

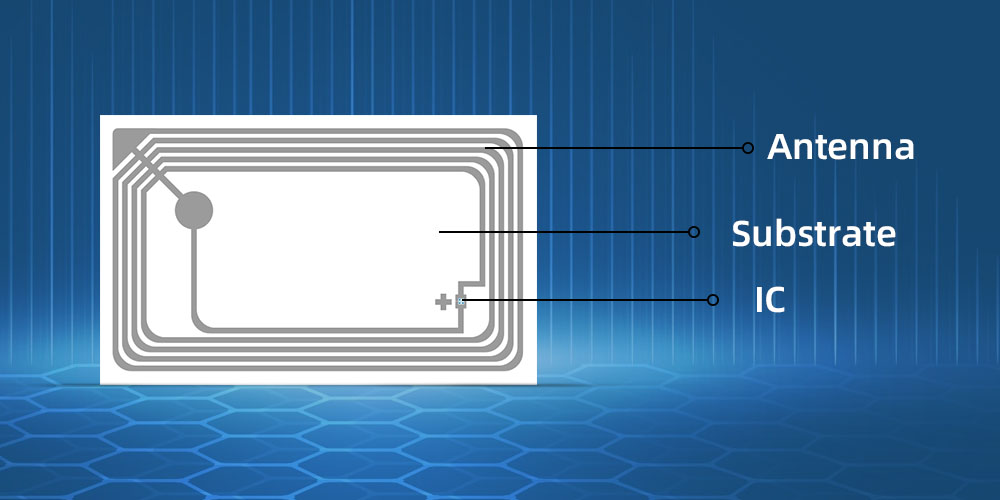

Components of an RFID Tag

The RFID tag is one of the important components of the RFID system, which is mainly composed of three parts: chip, antenna, and substrate. The chip contains a logical control unit, memory, and transceiver for decoding, decrypting, and error checking. The antenna is used to receive RF signals from the reader or to transmit its identification information. The substrate is the carrier of the chip and the antenna, holding them together.

These three parts are indispensable. They determine and affect the performance and application environment of RFID tags. Different chip, antenna design, and substrates of different materials can be combined into RFID tags with different functional characteristics to meet a variety of requirements.

RFID Chip (IC)

The RFID chip, otherwise known as IC (short for Integrated Circuit), is usually designed and manufactured by semiconductor manufacturers. It is a small microprocessor, which has a logic unit that makes decisions and provides memory to store data.

Integrated circuits need the power to operate. This power can come from the battery on the tag (in the active tag) or the radio energy radiated by the interrogator’s antenna (in the passive tag). Part of the integrated circuit is used to control the power supply.

Integrated circuits can integrate a large number of micro transistors into a small chip. In 2006, the chip area ranged from a few square millimeters to 350 mm ², with up to a million transistors per mm ².

In recent years, with the development of semiconductor technology, integrated circuits are available in a smaller size, so that each chip can encapsulate more circuits. The number of transistors in integrated circuits doubles every 1.5 years. This increases the capacity per unit area, reducing costs, and increasing functionality. The tag IC is more efficient in power usage and requires less power to operate, increasing the reading range of the passive tag.

RFID Chip Classification

| Category | Frequency | Protocol | Common Chip |

|---|---|---|---|

| LF RFID Chip | 125kHz~134.2kHz | ISO7814, ISO7815 | TK4100,EM4200,T5577,EM4305,SIC7888 |

| HF RFID Chip | 13.56MHz | ISO14443, ISO15693,ISO18000-3M | MIFARE Classic EV1,NTAG 213/215/216, SRI512, ICODE SLIX |

| UHF RFID Chip | 860MHz~960MHz | ISO/IEC 18000-6C | Higgs 3, Higgs 4, EM4325, EM4423, Monza 4QT, Ucode HSL |

RFID Tag Antenna

The RFID tag antenna is a kind of communication induction antenna connected with the tag integrated circuit, which is an important part of RFID tag transponder. The antenna receives the signal from the interrogator, then transmits or reflects the received signal according to the type of tag. For active tags, it transmits signals; for semi-passive or passive tags, it reflects the signals. For passive tags, the antenna also collects energy from the radio waves and feeds the integrated circuit.

The antenna geometry is determined by the frequency at which the tag works. Although the tag may use the same IC, antenna design changes allow the tag to have completely different characteristics and behavior. The antenna may take the shape of a spiral coil, a single dipole, a double dipole (one perpendicular to the other), or a folded dipole.

Among these basic types, there are many variations in antenna shape, depending on the specific requirements of the application and the abilities of the designer. Different frequencies and materials can also affect antenna design. For example, the HF antenna and UHF antenna have different antenna designs due to their different working principles. There are also differences in the fabrication of antennas. Basic parameters and technical indicators of the two antennas (as shown in the following table):

| High Frequency Antenna | ||

| Material | Frequency | |

|---|---|---|

| aluminum | 30μm/10μm | 13.56±0.2M Hz |

| PET | 38μm | |

| Ultrahigh Frequency Antenna | ||

| Material | Frequency | |

| aluminum | 10μm | 860~960MHz |

| PET | 50μm | |

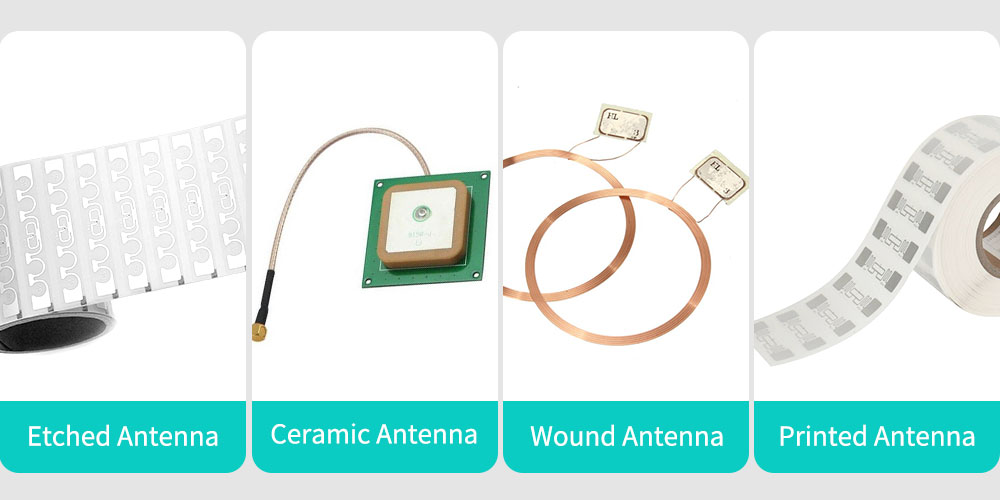

Antenna Classification

Due to the difference in wire material, material structure, and manufacturing process, the RFID tag antenna can be divided into the following categories: etched antenna, printed antenna, wound antenna, addition antenna, ceramic antenna, etc.

1、Etched Antenna (copper etched antenna and aluminum etched antenna)

The etched antenna is the mainstream manufacturing process of RFID antenna, which has the highest market share and the most mature technology. There are two methods: the traditional etching method and the precision etching method.

The biggest difference between the two is that the precision etching antenna has smooth lines and small tolerance of line width. The minimum line width of aluminum etching can reach 0.1mm, and the minimum line width of copper etching antenna can reach 0.05mm, but the cost will be relatively high.

From the material, it can be divided into PET antenna, PI (polyimide) antenna, PCB antenna, etc., in which PI antenna is mainly used for high-temperature resistance, chemical resistance, and other special environments, while PCB antenna is suitable for anti-metal tags.

2、Printed Antenna (including 3D printed antenna)

The printed antenna is to directly use special conductive ink or silver paste to print the antenna circuit on the substrate. The more mature process is gravure printing or screen printing. It has the advantage of no etching, no obvious pollution, short technological process, delivery fast,and low cost.

However, due to the large resistance of conductive ink or silver paste and the great difference in the performance of conductive materials, there will be a decline in performance over time. And there are still some problems in the consistency and durability of the UHF antenna.

3、Wound Antenna (copper wound antenna)

Copper-wound antenna, using the coil winding method, wound the coil on the winding tool and fixed it. It wound a certain number of turns according to different frequency requirements. The antenna is mainly used for low-frequency (125-134 kHz) and high-frequency (13.56MHz) tags, but rarely for UHF (except for the antenna coupled with UHF micromodules).

The biggest advantage is that it still shows good performance in the case of small antenna area or volume. But its disadvantages: low production efficiency, high cost, high product thickness, not resistant to bending.

4、Ceramic Antenna

The ceramic antenna uses ceramic substrate (alumina) as the substrate and silver paste as the wire body. And the antenna pattern is printed on the substrate, and then sintered at high temperature to form an antenna circuit.

Ceramic Antenna features stable performance and strong adaptability to the environment. But it costs too high and not easy to install. It is suitable for UHF anti-metal tags and car windshield anti-disassembly tags.

5、Fragile Antenna

The characteristic of the fragile antenna is to realize the uniqueness of the RFID tags. It is often made into a label and affixed to a flat and clean surface such as sealing, glass, plastic, carton packaging. And when you uncovered it, the antenna will be destroyed and cannot be recycled.

RFID Tag Substrate

The RFID tag substrate is a carrier that holds the RFID chip and antenna together. The tag antenna is deposited or printed on the substrate, and the IC is then attached to this antenna. Substrates are usually made of flexible materials such as PVC,PET, Paper, but can also be made of rigid materials like PCB.

The substrate must be able to withstand a variety of environmental conditions, such as high temperature, high humidity, sunlight, chemical corrosion, wear, and tear, etc. And substrate materials must provide dissipation of electrostatic accumulation, smooth printed surfaces for antenna layout, durability and stability under various operating conditions, and mechanical protection of antennas, chips, and their interconnections.

Besides, the substrate material may affect the design frequency of the antenna; therefore, the influence of the substrate material must be taken into account when properly tuning the antenna.

RFID Tag Encapsulation

There are many packaging forms of RFID tags, and they are not restricted by size and standard shape, and their composition is also different. Therefore, packaging processes such as antenna manufacturing, bump formation, chip bonding, and interconnection are also diverse.

1、RFID Inlay

RFID inlay is the simplest form of RFID tag. You can see it as a semi-finished because all the RFID tags start as an inlay, but actually, it is an RFID label with full-featured. An inlay is made of IC, antenna, which is attached to the substrate.

2、RFID Label

Adhesive type: It is the most mainstream product in practical application. This label has an adhesive layer and easy to stick to the objects, suitable for air baggage labels, pallet labels, etc.

Tag type: It is widely used in clothing and articles, which is characterized by the compact size and can be recycled.

3、RFID Card

Laminated Type: There are two types: melting pressure and sealing pressure. Melting and pressing is made of inlay sheet and upper and lower PVC sheets by heating and pressing. The PVC material is fused with inlay and then punched and cut to the specified size.

Gluing Type: The upper and lower materials of Transponder are glued together by paper or other materials by cold glue, and then die-cut into cards of various sizes.

4、Special-shaped Tag

RFID wristbands: RFID wristbands are easy to wear and are available in a variety of materials, such as silicone wristbands, woven wristbands, paper wristbands, PVC wristbands, which can be used disposable (such as medical) or reused. They are widely used in amusement parks, beach baths, large-scale events or activities, etc.

RFID Keyfob: It is generally made of ABS and glue dripping materials, small and exquisite. RFID keyfob comes in a variety of shapes, such as water droplets, circles, squares, animal shapes, etc. It is easy to carry and can be hung on a keychain or bag, widely used for access control management.

Animal Tags: Animal labels are different from other labels. For the convenience of animal management, animal labels are often in the form of injection glass tubes, ear tags, buckle bracelets, embedded identification pins, etc.

For more information about RFID, you can follow us or contact us directly. Xinyetong, a reliable supplier, focuses on RFID for 12 years. We can provide any RFID products and have the ability to give you a perfect solution.

혹시 예전에 한국에 rfid usn방식이라는게 있었나요?

900mhz대에선 현재 유통되는게 uhf방식이던데 예전 방식의 카드가 읽히지를 않는것 같은데

해결 방법이 없을까요???