RFID inlays, RFID tags, and RFID Labels form the core of your RFID system. But can you differentiate them?

While most people use these terms interchangeably, there are slight physical and functionality differences among them. This article explores all the differences between RFID inlays, RFID tags, and RFID labels. Read on.

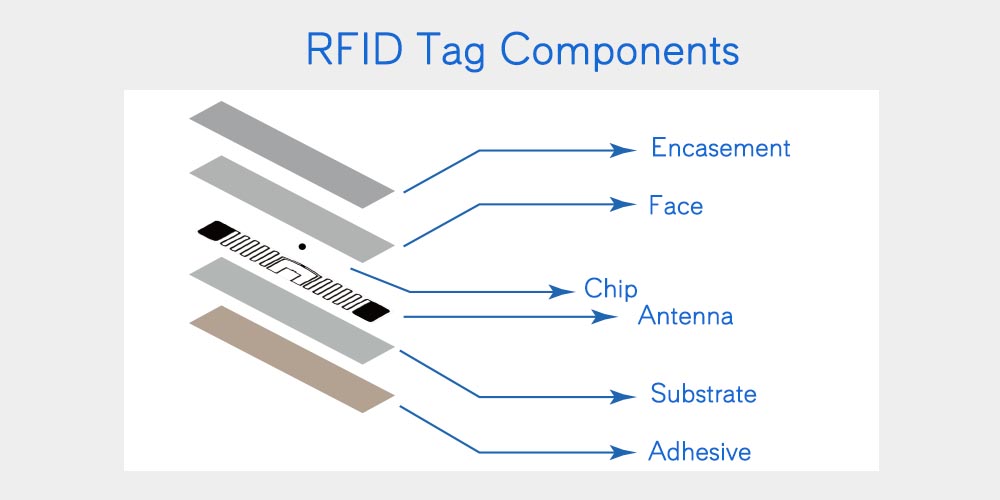

RFID Tag Components

RFID tags comprise an integrated circuit (IC), an antenna, and a substrate. To help you understand all the differences between tags, inlays, and labels, we’ll define the parts of RFID tags as below:

- Integrated Circuit. This part is also known as an RFID chip. It is the part of the tag that is responsible for data storage, handling, and processing.

- Antenna. This part receives radio waves from an interrogator and sends data back to the reader. It takes up the largest space.

- Substrate. A substrate is a matter that holds together the IC and the tag antenna.

- Face. A face is a thin layer made of clear/white plastic or paper. It is used to cover the antenna and the chip.

- Encasement. Refers to a cover that encloses the IC, antennae, and substrate. It is made from PET, plastic, or paper.

- Adhesive. Refers to the material used to attach a tag to an item.

RFID Inlays, RFID Tags, RFID Labels – What Are They?

Now that you understand the RFID system, let’s delve into the definitions of an RFID inlay, an RFID tag, and an RFID label.

1.RFID Inlay

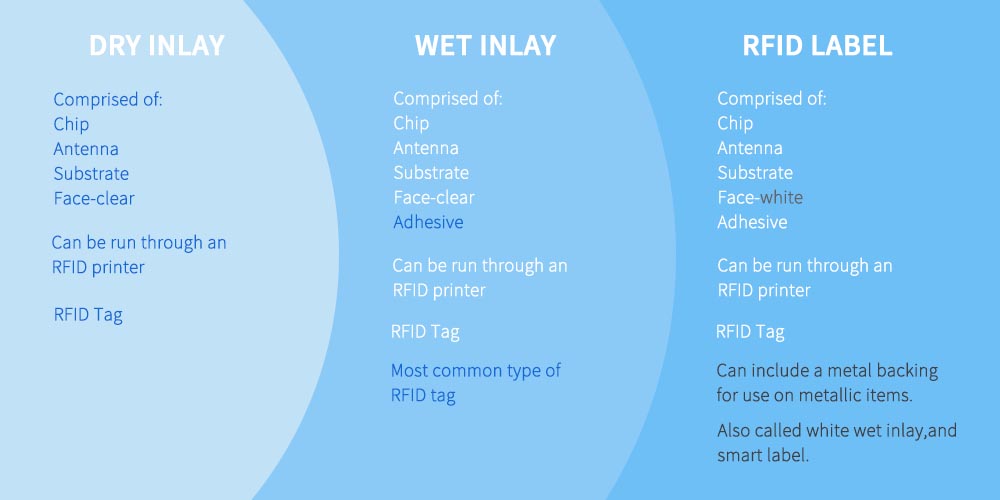

An RFID inlay comprises an integrated circuit, an antenna, and a substrate. The antenna is made from aluminum, silver, and copper, and it is bonded to a polyethylene terephthalate (PET). The PET can either be wet or dry.

- Wet RFID Inlay. This inlay has a face containing an adhesive. This feature gives them a peel-and-stick effect, thus making them relatively easy to apply.

- Dry Inlay. This inlay lacks an adherent. As such, you will require to use an external adherent or other substances that can help you stick it to the asset.

RFID inlays are relatively affordable and easy to use. For inlays, the substrate/PET is made of a clear/transparent plastic.

2.RFID Label

An RFID label contains all the elements of the tag. Just like an RFID inlay, a label includes an antenna, chip, and substrate. They are also called smart labels.

An RFID label is an RFID inlay embedded on paper. It is an ideal method to track products during shipping.

3. RFID Tag

This refers to an encapsulated RFID chip and antennae. The encapsulation is meant to protect the tag’s components and guarantee ease of application.

An RFID tag can either be active or passive. The active ones come with a battery, which guarantees a relatively wider read range. On the contrary, the passive ones rely on the signals from a reader to power up.

RFID Inlays, RFID Tags, RFID Labels – Are they Different?

While these tracking methods have a similar working rationale, a few physical differences set them apart. Here’s an analysis:

- RFID Inlays vs. RFID Labels

An RFID inlay is the functional part of an RFID label. The inlay can be used alone by simply attaching it to the target asset. Dry inlays lack adherent, and you’ll be required to get an external adherent to fix it in place.

To get an RFID Label, you must have an RFID inlay with an adhesive face. The wet inlay is then placed on the back of the RFID label. The adhesive side should face away from the label.

This ensures that the label has a face with a continuous adhesive agent. The label can then be attached to your assets for tracking, identification, and inventory management.

- RFID Tags vs. RFID Inlays & RFID Labels

RFID tags are an inlay that contains a casing. It has the IC and the antennae encapsulated in a cover. They do not necessarily have an adhesive.

Unlike smart labels, you will be required to have an external attachment method to enjoy its full benefits. Always ensure that you attach it in a location with no obstructions to pick the reader’s radio waves without interruptions.

- RFID Inlays, RFID Tags, RFID Labels – Cost Comparison

Labels and wet inlays are the most common and affordable types of RFID tags. The affordability is because of the following reasons:

- Accessibility. Both inlays and labels are low cost. As such, they become the best option for retailers and other small scale users.

- Applicability. Labels have an adhesive, thus making them easy to use. They are ideal for peel-and-stick applications. The fact that you’ll not require an external adhesive makes them even more affordable.

When compared with RFID labels and inlays, hard RFID tags are relatively expensive.

- Comparison Based on Ability to Print

Before you settle for your ideal tag, you should consider whether the information contained therein is printable.

Overall, you can use the RFID labels and RFID inlays with an RFID printer. However, the printed text will be clearer when using RFID labels.

As such, you should purchase the RFID labels if you intend to print the information regularly. The clarity is mainly attributed to the label’s white background instead of the clear ones associated with inlays.

RFID Inlays, RFID Tags, RFID Labels – Which One Should You Choose?

These tags have almost similar functionalities. They will all help you to track assets and manage your inventories. However, there are a few factors that can affect your choice. They include:

- The Use. What do you want to track? If you intend to track an asset on transit, you should consider getting an active RFID tag. On the other hand, inlays and labels would be best if you intend to attach them to wristbands and other temporary assets.

- Cost. Like we’ve earlier indicated, inlays and labels are the most affordable tags you can get in the market today. As such, you can choose them if you intend to use them once. For example, in managing the event’s attendance.

It doesn’t matter the RFID tracking technique you apply; you should ensure that you get the best out of your investment. Select one that will resolve your problems and improve your operations.