Taking inventory of a store with 15000 pieces of clothes in stock, using barcode technology, it needs to takes four people eight hours to complete with the highest accuracy of 86 percent. With RFID, it can be done by one person in an hour, and more importantly, the accuracy is close to 100%. Which way would you choose? Maybe everyone is willing to choose RFID technology. Nowadays, more and more clothing brands and large clothing supermarkets, such as Zara, Uniqlo, Highland House, Prada, DiCarlo, are using RFID technology to help them achieve intelligent clothing management. Today, let’s take a look at how RFID has changed the clothing industry.

Barcode to RFID Tag Transition

Nowadays, most apparel enterprises use barcodes for data collection in the whole process, including production, warehouse, store, and sales. However, with the expansion of the business scale of garment enterprises, inventory management becomes more difficult.

Clothing warehouses are mostly small-batch and multi-batch distribution. However, the way of scanning goods one by one based on barcode cannot meet the efficiency requirements of receiving and dispatching operations in the peak period, and the mismatch of goods often occurs. RFID tags can solve the problem, which has the advantages of a large amount of written information, changeable information, long service life, high security, etc.

Common Types of RFID Clothing Tags

| Coated Paper RFID Sticker |

RFID stickers are the most common RFID tag used in clothing management. They can be directly attached to the clothing tag without changing the existing hanging tag mode to achieve the visibility of garment supply chain inventory, reduce the shortage of goods, and achieve easy scheduling. There are many sizes, crafts, chips that you can choose according to the requirements.

You also can call it RFID care labels, usually made of soft woven fabric material. It can be sewed on the inside of the clothing, completed in the factory production process. It has the features of waterproof and not easy to lose, good anti-counterfeiting, and best anti-channeling. A variety of label styles can be customized according to customer requirements, new products, and high-end brand clothes prefer it.

Clothing RFID Hang Tag is to embed the RFID chip directly into the clothing tag to achieve the integration of the chip and tag, more integrated, and more beautiful. It can be customized according to the needs of the garment brand. The cost is relatively high, and it is suitable for new or high-end clothing products, as well as clothing brands with high aesthetic requirements.

| RFID Apparel Hard Tag |

RFID clothing hard tag is the UHF+EAS dual-frequency tag. It integrates RFID technology and electronic anti-theft technology in one of the hard labels, mainly used for clothing stores to prevent theft and reduce losses. This tag is usually made of ABS plastic shell, durable and reusable. Therefore, it can be recycled and reused after garment retail.

This is a common RFID laundry tag with good heat resistance. There are many other features, like waterproof, pressure resistant, alkali resistance, popularly used in industrial laundry, linen rental industry. This tags can withstand the harsh environment of the laundry process, providing the perfect solution for automatic tracking of clothes and intelligent sorting of clothes.

Application of RFID in Clothing Industry

After decades of development, RFID has been widely used in the clothing industry, including clothing production, warehousing, logistics and transportation, distribution, store sales management, etc. It has gradually become an indispensable technical tool and means for brand clothing factories to improve clothing management, reduce management costs, and enhance core competitiveness.

1\ Garment Production

Production Management

IIn the production process, a series of necessary information such as commodity number, color number, specification, executive standard, lining, fabric are written into the RFID tag. And the label is bound to the ready-made garment in the form of a hanging tag to ensure that each piece of clothing has a unique ID, which can be used for clothing production management control and scheduling to improve the efficiency of clothing production management.

Clothing Anti-Counterfeiting

Many large clothing brands use RFID technology for anti-counterfeiting, enhancing their brand building, and improving a better experience for consumers. In the process of clothing production, relevant anti-counterfeiting information can be written into NFC clothing tags and hung on the garment. So consumers can use their NFC phones to scan to make sure the clothes are genuine.

Making Smart Clothes

It has become a reality that RFID technology can turn an ordinary piece of clothing into a smart one. Many clothing brands around the world have produced smart clothes, implanting NFC tags on buttons or cuffs to achieve some interactive functions. In this way, it gives clothes a sense of science and technology, increases the selling points of clothes, and attracts more consumers who pursue personality and technology.

2\ Clothing Warehouse Application

Inbound and Outbound Data Collection

When the clothing production from the factory goes through the formalities of storage, the RFID channel machine or RFID reader can be used to collect and input the clothing quantity, model, and other information, which can quickly complete the check-in and out of the warehouse. With RFID technology as the core, combined with mechanical design, a variety of sensors, electromagnetic shielding, automatic control, and other technologies, it can also achieve a single batch reading function.

Warehouse Automatic Sorting

RFID automatic sorting system, that is, using RFID technology to achieve automatic sorting of clothing, as long as the clothing on the conveyor belt, clothing can be sorted and packed following the requirements. RFID technology can sort goods continuously and in large quantities, and the sorting error rate is low, and the sorting operation is mechanized.

Warehouse Inventory

Both manufacturers and clothing stores can use RFID readers for warehouse inventory. Customers can automatically analyze the RFID garment tags read by the reader to know the data of garment, including actual quantity, color, model, to ensure the balance of inventory and timely replenishment. That can avoid the shortage or broken code of a type of clothing in the clothing store, and ensure the needs of customers.

3\ Logistics Management

The benefits of RFID technology in clothing logistics are reflected in logistics management efficiency, logistics cost, delivery control, etc. RFID technology can standardize the clothing logistics operation, shorten the operation flow and time, reduce the labor cost to reduce the operating cost, increase the throughput of the logistics link, and improve the efficiency of logistics management.

Moreover, RFID can minimize the shipping error rate. Shipping errors mainly refer to the shortage of original cases and packing box errors, and these two major problems can be reduced to a minimum by using RFID technology.

4\ Clothing Store Management

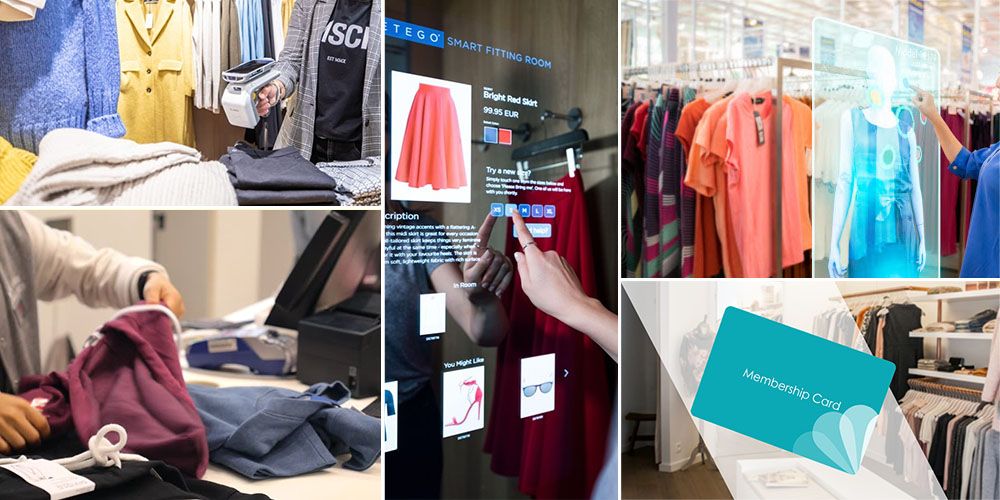

Wisdom Store

The intelligent clothing store system is based on RFID technology and realizes intelligent clothing management through RFID equipment. The RFID system in the garment industry provides efficient technical means for each store, improves the efficiency of store management, simplifies the process of clothing management, reduces the labor intensity of store managers, and provides consumers with a faster shopping process.

Store Receipt

After receiving the goods, the clothing store does not need to open the box and scan the bar code one by one to confirm the receipt. By scanning the periphery of RFID hand-held intelligent terminal, they can get the number of goods in batches immediately, and automatically complete the matching with the order, fast and accurate. Meanwhile, the data is sent back to the background for processing. The background store management system will automatically modify the inventory quantity of stores to improve the accuracy and efficiency of order execution and ensure the accurate inventory of goods.

Store Inventory

When taking inventory, using an RFID handheld terminal automatically scan and read the corresponding clothing information of the label, count and upload the data to the store background management system to update the inventory information in time.

When looking for goods, using the RFID handheld terminal, by locking the specified clothing information and pressing the hint of the beep within a certain distance, you can quickly confirm the location of the clothes you are looking for.

Intelligent Cashier

Combined with ultra-high-frequency cashier readers, consumers only need to put the selected items on the cashier’s read-write platform. RFID information of clothes will be automatically read and quickly generated to complete the settlement. There is no need to find the tag/bar code scanning for confirmation one by one to reduce the queuing time.

Intelligent Fitting

When a customer picks up a garment and enters the fitting room, the RFID tagged garment will sense and wake up the associated intelligent fitting screen, and display the corresponding clothing information and in-store matching recommendations.

At the same time, it will record the behavior of consumers, and the data will be sent to the background of the smart clothing store management system. Combined with sales data, you can analyze the operating conditions of the stores and find out which styles are more popular and which ones have been tried more and sold less.

Clothing Anti-theft

Attach a UHF+EAS tag to the clothing item, and when the tagged clothing leaves the store, the RFID access device will detect the behavior and beep it. Using UHF+EAS can solve the problem of merchandise theft in stores.

VIP Customer Management

When a customer with an RFID membership card arrives at the store, the welcome word can be displayed on the big screen, and the shopping guide will know the relevant member information and shopping habits by the intelligent terminal. Combined with the information of the magic mirror and fitting room, we can also analyze customers’ purchasing habits, purchasing desires, and other information, providing a better service to customers.

Conclusion

The clothing industry is a highly integrated industry, set design research and development to produce garments again to transport sales as one. Traditional clothing supply chain tends to consume enormous labor resources and capital cost in these processes but generally results in inefficiency. Therefore using RFID technology in garment management is the key to improve clothing management and make it intelligent and informational.

Relevant articles

- Why are more libraries using RFID technology?

- RFID Animal Tracking and Identification

- RFID for Access Control Management You Would Like to Know

- The Ultimate Guide to Know RFID Asset Management

- RFID for Laundry: How it works? What the benefits?

- Deeply Dug: RFID for Tracking

- 9 Common Applications RFID in Hospitals

- How does RFID revolutionize manufacturing?

you are in reality a just right webmaster The site loading velocity is incredible It seems that you are doing any unique trick In addition The contents are masterwork you have performed a wonderful task on this topic